Advanced Industrial Plasma Technologies

PVD Sources and Systems

Download our PVD brochure!

PVD Equipment Specification

RFQ Questionnaire

About our sources

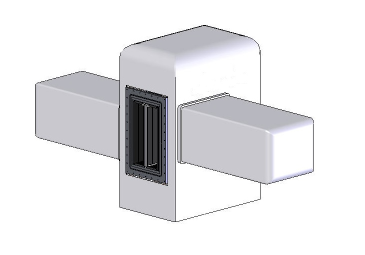

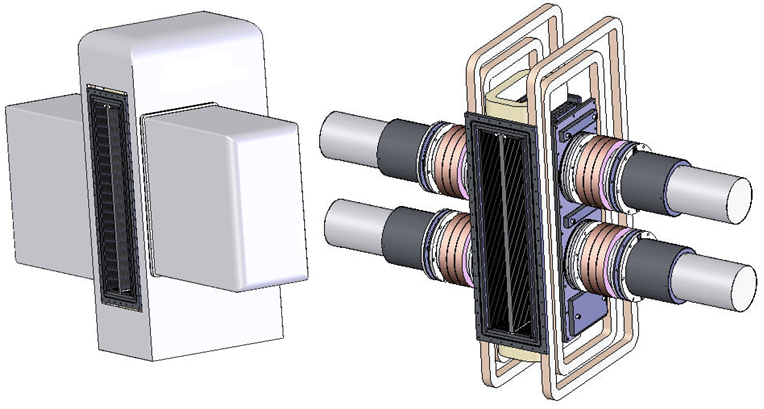

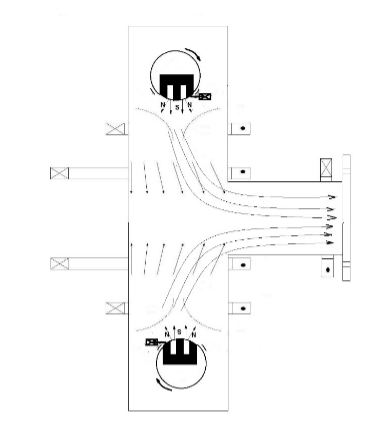

Our LAFAD™ and FAAMS™ unidirectional dual filtered cathodic arc deposition metal vapor plasma sources are designed to meet the diverse needs of our customers, either retrofitting with existing PVD chambers, or as a source component within advanced surface engineering equipment. The sources are available in two basic designs: one with straight end opening welded to the chamber wall; and another with regular flange and Viton O-ring seal. Source control modules are provided, and can be easily integrated into vacuum system controls.

While NPE does not provide coating services or equipment manufacturing directly, clients can use our technology via licensing and technology transfer as well as ordering equipment and surface engineering services from NPE's partners with full NPE technical support. If you are a commercial coating services provider or coating equipment manufacturer and are interested in including our PVD and/or PACVD technologies in your offerings, please contact us to license the technologies, along with full technical support.

Installation and integration

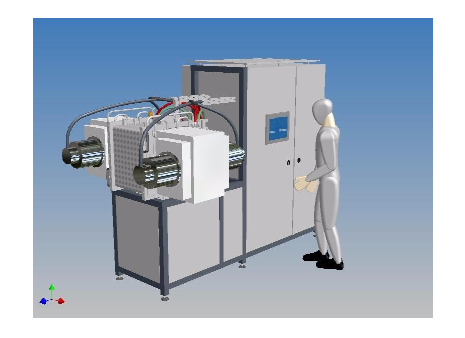

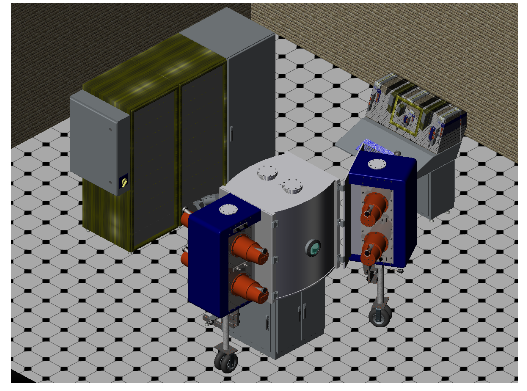

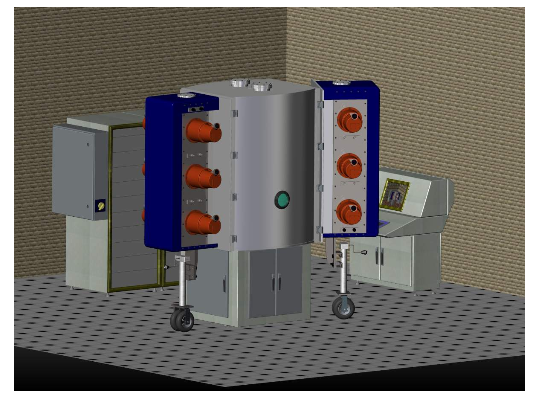

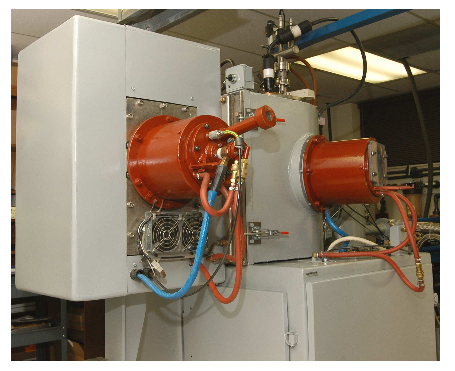

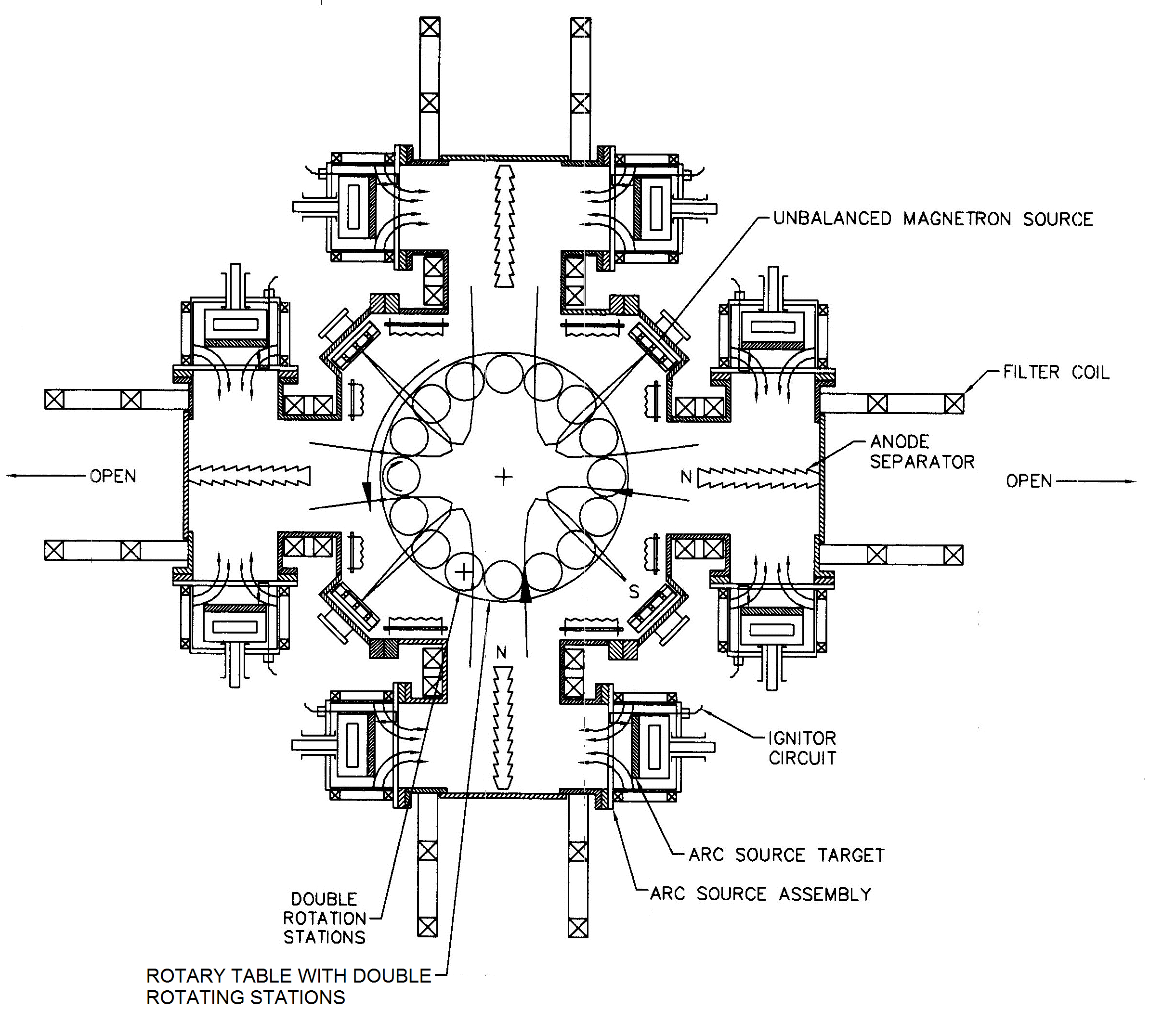

NPE’s DCAD, LAFAD™ and FAAMS™ metal vapor plasma sources can be integrated into existing PVD systems, or installed as primary sources for stand-alone systems. The LAFAD plasma sources can be integrated into different chamber layouts. NPE and its predecessors have built a number of different batch coaters utilizing one and two LAFAD sources as well as hybrid filtered arc assisted magnetron sputtering systems. NPE has developed, constructed and sold several systems based upon advanced DCAD, LAFAD™ and FAAMS™ technologies. The first model of NPE’s LAFAD-500C- 1 batch coater utilize one LAFAD-500C dual unidirectional plasma source and two direct cathodic arc sources in one chamber layout. This system has a carousel multi-satellites substrate table with coating area 16” dia x 12” tall. LAFAD™ unidirectional dual filtered arc source can utilize both billet-style and planar- or rotary-style primary cathode targets. NPE provides comprehensive source installation and technical support!The DCAD Source

LAFAD Sources

| # of DCAD sources | 2 |

| DCAD source assembly height | 350 mm (the exit flange diameter of a single DCAD-250-C source) |

| Plasma duct chamber height | 500 mm |

| Plasma duct chamber width | 400 mm |

| Deposition area height (with ±10% coating thickness nonuniformity) | 300 mm |

| # of DCAD sources | 4 |

| DCAD source assembly height | 750 mm |

| Plasma duct chamber height | 900 mm |

| Plasma duct chamber width | 400 mm |

| Deposition area height (with ±10% coating thickness nonuniformity) | 600 mm |

| # of rectangular or rotary DCAD-750R sources | 2 |

| DCAD-750R source assembly height | 750 mm |

| Plasma duct chamber height | 900 mm |

| Plasma duct chamber width | 400 mm |

| Deposition area height (with ±10% coating thickness nonuniformity) | 600 mm |

| # of DCAD sources | 6 |

| DCAD source assembly height | 1150 mm |

| Plasma duct chamber height | 1300 mm |

| Plasma duct chamber width | 400 mm |

| Deposition area height (with ±10% coating thickness nonuniformity) | 900 mm |

| # of DCAD-1150R sources | 2 |

| DCAD-1150R source assembly height | 1150 mm |

| Plasma duct chamber height | 1300 mm |

| Plasma duct chamber width | 400 mm |

| Deposition area height (with ±10% coating thickness nonuniformity) | 900 mm |

LAFAD Systems

| # of LAFAD sources attached to side walls of the main chamber | 1 |

| # of DCAD sources | 2 |

| Chamber height | 600 mm |

| Chamber diameter | 600 mm |

| Deposition area height (with ±10% coating thickness nonuniformity) | 300 mm |

| # of LAFAD sources attached to side walls of the main chamber | 1 |

| # of DCAD sources | 4 |

| Chamber height | 1000 mm |

| Chamber diameter | 600 mm |

| Deposition area height (with ±10% coating thickness nonuniformity) | 600 mm |

| # of LAFAD sources attached to side walls of the main chamber | 1 |

| # of DCAD sources | 6 |

| Chamber height | 1400 mm |

| Chamber diameter | 800 mm |

| Deposition area height (with ±10% coating thickness nonuniformity) | 900 mm |

| # of LAFAD sources attached to side walls of the main chamber | 1 |

| # of DCAD sources | 6 |

| Chamber height | 1400 mm |

| Chamber diameter | 800 mm |

| Deposition area height (with ±10% coating thickness nonuniformity) | 900 mm |

| # of LAFAD sources attached to side walls of the main chamber | 2 |

| # of DCAD sources | 4 |

| Chamber height | 600 mm |

| Chamber diameter | 600 mm |

| Deposition area height (with ±10% coating thickness nonuniformity) | 300 mm |

.png)

| # of LAFAD sources attached to side walls of the main chamber | 2 |

| # of DCAD sources | 8 |

| Chamber height | 1000 mm |

| Chamber diameter | 600 mm |

| Deposition area height (with ±10% coating thickness nonuniformity) | 600 mm |

| # of LAFAD sources attached to side walls of the main chamber | 2 |

| # of DCAD sources | 12 |

| Chamber height | 1400 mm |

| Chamber diameter | 800 mm |

| Deposition area height (with ±10% coating thickness nonuniformity) | 900 mm |

FAAMS Sources

| # of DCAD sources | 2 |

| DCAD sources height | 350 mm |

| Plasma duct chamber height | 500 mm |

| Plasma duct chamber width | 400 mm |

| 2 planar-rectangular or rotary-cylindrical magnetrons, 3"width/dia, height | 400 mm |

| Deposition area height (with ±10% coating thickness nonuniformity) | 300 mm |

| # of DCAD sources | 4 |

| DCAD sources height | 750 mm |

| Plasma duct chamber height | 900 mm |

| Plasma duct chamber width | 400 mm |

| 2 planar-rectangular or rotary-cylindrical magnetrons, 3"width/dia, height | 700 mm |

| Deposition area height (with ±10% coating thickness nonuniformity) | 600 mm |

| # of DCAD sources | 6 |

| DCAD sources height | 1150 mm |

| Plasma duct chamber height | 1300 mm |

| Plasma duct chamber width | 400 mm |

| 2 planar-rectangular or rotary-cylindrical magnetrons, 3"dia, height | 1000 mm |

| Deposition area height (with ±10% coating thickness nonuniformity) | 900 mm |

FAAMS Systems

| # of LAFAD sources attached to side walls of the main chamber | 1 |

| # of DCAD sources | 2 |

| Chamber height | 600 mm |

| Chamber diameter | 600 mm |

| Number of planar-rectangular or rotary-cylindrical magnetrons | 2 |

| 2 planar-rectangular or rotary-cylindrical magnetrons, 3"width/dia, height | 400 mm | Deposition area height (with ±10% coating thickness nonuniformity) | 300 mm |

| # of LAFAD sources attached to side walls of the main chamber | 1 |

| # of DCAD sources | 4 |

| Chamber height | 1000 mm |

| Chamber diameter | 600 mm |

| Number of planar-rectangular or rotary-cylindrical magnetrons | 2 |

| Planar-rectangular or rotary-cylindrical magnetrons, 3"width/dia, height | 700 mm | Deposition area height (with ±10% coating thickness nonuniformity) | 600 mm |

| # of LAFAD sources attached to side walls of the main chamber | 1 |

| # of DCAD sources | 6 |

| Chamber height | 1400 mm |

| Chamber diameter | 800 mm |

| Number of planar-rectangular or rotary-cylindrical magnetronss | 2 |

| Planar-rectangular or rotary-cylindrical magnetrons, 3"width/dia, height | 1000 mm | Deposition area height (with ±10% coating thickness nonuniformity) | 900 mm |

| # of LAFAD sources attached to side walls of the main chamber | 2 |

| # of DCAD sources | 4 |

| Chamber height | 600 mm |

| Chamber diameter | 600 mm |

| Number of planar-rectangular or rotary-cylindrical magnetrons | 4 |

| Planar-rectangular or rotary-cylindrical magnetrons, 3"width/dia, height | 400 mm | Deposition area height (with ±10% coating thickness nonuniformity) | 300 mm |

| # of LAFAD sources attached to side walls of the main chamber | 2 |

| # of DCAD sources | 8 |

| Chamber height | 1000 mm |

| Chamber diameter | 600 mm |

| Number of planar-rectangular or rotary-cylindrical magnetrons | 4 |

| Planar-rectangular or rotary-cylindrical magnetrons, 3"width/dia, height | 700 mm | Deposition area height (with ±10% coating thickness nonuniformity) | 600 mm |

| # of LAFAD sources attached to side walls of the main chamber | 2 |

| # of DCAD sources | 12 |

| Chamber height | 1400 mm |

| Chamber diameter | 800 mm |

| Number of planar-rectangular or rotary-cylindrical magnetrons | 4 |

| Planar-rectangular or rotary-cylindrical magnetrons, 3"width/dia, height | 1000 mm | Deposition area height (with ±10% coating thickness nonuniformity) | 900 mm |

| # of LAFAD sources attached to side walls of the main chamber | 4 |

| # of DCAD sources | 24 |

| Chamber height | 1400 mm |

| Chamber diameter | 1000 mm |

| Number of planar-rectangular or rotary-cylindrical magnetrons | 8 |

| Planar-rectangular or rotary-cylindrical magnetrons, 3"width/dia, height | 1000 mm | Deposition area height (with ±10% coating thickness nonuniformity) | 900 mm |

©2018 Nano-Product Engineering, LLC